Key Ingredient

Acidic metal chelating agents

pH Range

2.5 - 6.0

Applications

Descaling of metal fouling in industrial systems

Key Ingredient

Metal chelating agents and acids

pH Range

3.0 - 6.5

Applications

Foulant removal in water treatment systems

Key Ingredient

Specialized acid-based formulation

pH Range

3.5 - 6.0

Applications

Descaling and metal fouling removal in industrial systems

Key Ingredient

Organic acids

pH Range

1.5 - 2.5

Applications

Removal of metal scales

Key Ingredient

Organic acids

pH Range

2.0 - 3.0

Applications

Scale removal in heat exchangers

Key Ingredient

Organic acids

pH Range

2.0 - 4.0

Applications

Effective in hard-to-remove metal scales

Slagging, and Corrosion

Biomass combustion has advantages like high volatility and fuel reactivity...

Read More

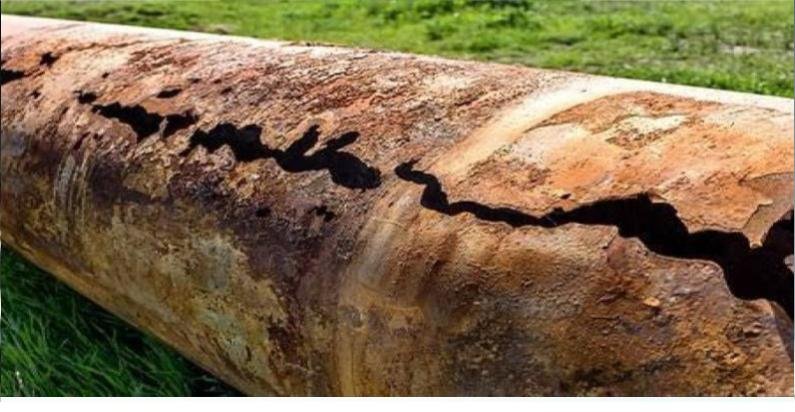

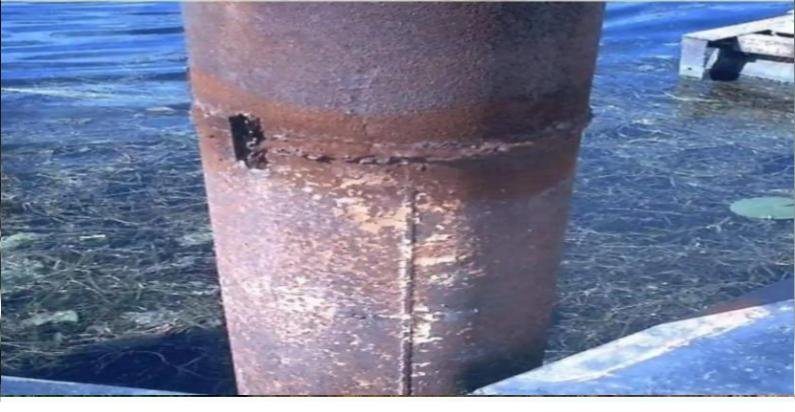

Key Ingredient

Rust removal agents

pH Range

2.0 - 4.0

Applications

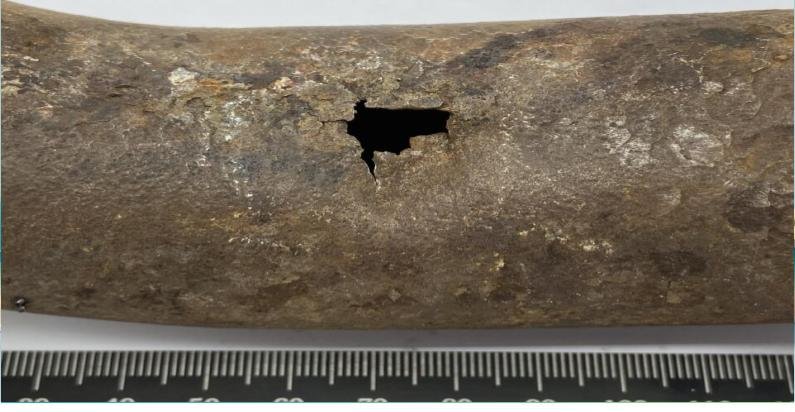

Removal of rust and oxidation from metals

Key Ingredient

Rust removal agents

pH Range

2.0 - 4.0

Applications

Removal of rust and oxidation from metals

Key Ingredient

Rust removal agents

pH Range

2.0 - 4.0

Applications

Rust removal from machinery, metal parts

Key Ingredient

Phosphoric acid, Nitric acid

pH Range

2.0 - 4.0

Applications

Passivation of stainless steel and other alloys

Key Ingredient

Citric acid, Phosphoric acid

pH Range

2.5 - 4.5

Applications

Passivation and cleaning of steel and stainless steel

Key Ingredient

Phosphoric acid, Hydrochloric acid

pH Range

1.8 - 3.8

Applications

Metal surface passivation and cleaning of alloys

Traditional Phosphonates

Polymeric scale inhibitors play a crucial role in water treatment...

Read More

Key Ingredient

Phosphonate compound

pH Range

5.0 - 7.5

Applications

Inhibiting scale formation in water treatment systems

Key Ingredient

Phosphonate compound

pH Range

5.5 - 7.0

Applications

Inhibiting scale formation in cooling towers and heat exchangers

Key Ingredient

Polymeric scale inhibitor

pH Range

6.0 - 8.0

Applications

Preventing scale in boilers and steam systems

Key Ingredient

Inorganic corrosion inhibitors

pH Range

5.0 - 9.0

Applications

Used for corrosion protection in industrial water systems

Key Ingredient

Inorganic corrosion inhibitors

pH Range

5.0 - 9.0

Applications

Used for corrosion protection in industrial water systems

Key Ingredient

Inorganic corrosion inhibitors

pH Range

5.0 - 9.0

Applications

Used for corrosion protection in industrial water systems

Key Ingredient

Phosphonate compound

pH Range

5.0 - 7.5

Applications

Inhibiting scale formation in water treatment systems

Key Ingredient

Phosphonate compound

pH Range

5.5 - 7.0

Applications

Inhibiting scale formation in cooling towers and heat exchangers

Key Ingredient

Polymeric scale inhibitor

pH Range

6.0 - 8.0

Applications

Preventing scale in boilers and steam systems

BENEFiCiARiES OF DADA

"We appreciate those who acquired and require DADA's sustainable solutions to tackle their critical water treatment."

BENEFiCiARiES OF DADA

"We appreciate those who acquired and require DADA's sustainable solutions to tackle their critical water treatment."